Analysis of Flow Through a Sudden Contraction in a Pipe

DOI:

https://doi.org/10.37934/sjotfe.7.1.19aKeywords:

Sudden contraction, CFD, pressure drop, pipe flow, streamline analysis, ANSYS FluentAbstract

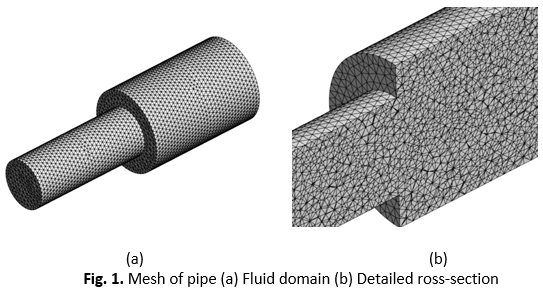

Internal flow through sudden-contraction pipes is analysed using Computational Fluid Dynamics (CFD) in this work, with a sole focus on five flow characteristics: velocity contours, pressure contours, streamlines, velocity distributions, and pressure distributions. Three pipe layouts with identical total lengths and constant outlet diameters of 30 mm and intake diameters of 50, 60, and 70 mm were analysed. Without adding further complications unrelated to these fundamental fluid-dynamic phenomena, the goal of this work is to give a focused assessment of how input diameter affects flow acceleration, pressure loss, and downstream recovery. The finite volume approach was used to perform all simulations under steady, incompressible flow conditions. Although temperature gradients were not enforced, the governing equations included the continuity equation, momentum equation, and, for completeness, the energy equation. A grid independence test made sure that mesh refinement had no appreciable impact on numerical findings, and a uniform meshing method and solver configuration were used for all geometries. For all configurations, a zero-gauge outlet pressure, uniform inlet velocity, and no-slip wall conditions were employed to ensure that performance variations came only from geometric variation and not from boundary-condition effects. The findings demonstrate that narrower, high-momentum jet areas are produced at the contraction by sharper velocity gradients caused by smaller inlet diameters. Accordingly, the 70 mm inlet achieves the smoothest transition and the lowest hydraulic loss, while the 50 mm inlet case shows the biggest pressure drop because of the stronger flow acceleration. In contrast to the more uniform and connected flow produced by the 70 mm inlet, streamlines exhibit sharper curvature and tighter convergence in the smaller inlet instance, highlighting these features. These variations are quantified by the velocity and pressure distributions along the centrelines, demonstrating that jet strength, recovery duration, and pressure stabilization are all directly impacted by contraction intensity. This concentrated research shows that input diameter is a key factor in determining the flow behaviour caused by contraction and maximizing hydraulic efficiency.