Hydrodynamic Behaviour in a T-Junction Pipe

DOI:

https://doi.org/10.37934/sjotfe.7.1.1724aKeywords:

T-junction pipe, hydrodynamic behaviour, CFD simulation, ANSYS Fluent, velocity distribution, pressure dropAbstract

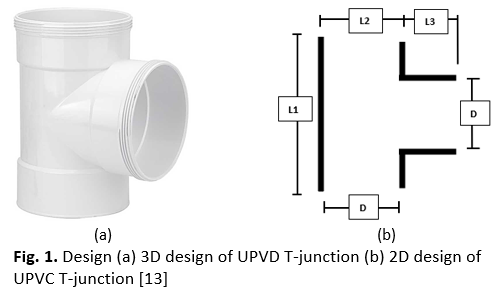

T-junction pipes are commonly used in water supply systems to divide or combine fluid flow. However, the sudden change in flow direction at the junction can cause complex flow behaviour such as high velocity regions, flow separation, recirculation, and pressure loss. Understanding these hydrodynamic characteristics is important to ensure efficient and reliable pipe system design, especially for small pipe sizes commonly used in domestic applications. This study investigates the flow behaviour inside equal T-junction pipes with diameters of 20 mm, 25 mm, and 32 mm using Computational Fluid Dynamics CFD. Three-dimensional models of the T-junction pipes were created and simulated using ANSYS Fluent. Water was selected as the working fluid, and a uniform inlet velocity of 1 m/s was applied to all cases. Turbulent flow conditions were considered using the standard k-epsilon turbulence model. A grid independence test was conducted to select an appropriate mesh size and ensure that the simulation results were not affected by the mesh resolution. Velocity and pressure contours were analysed to observe flow distribution and pressure variation at the junction region. The results show that pipe diameter strongly influences flow behaviour. The 20 mm T-junction produced the highest flow velocity, and the largest pressure drop due to the small diameter, which increases flow resistance. Strong velocity gradients and flow separation were observed at the junction. The 25 mm pipe showed smoother flow patterns with reduced velocity variation and moderate pressure loss. The 32 mm T-junction provided the most uniform flow distribution, and the lowest pressure drop, indicating improved flow stability and lower energy losses. In conclusion, larger pipe diameters result in smoother flow, reduced pressure loss, and better hydrodynamic performance. The findings of this study can help improve the design and selection of T-junction pipes for domestic and light industrial water distribution systems.