Pressure Drop Analysis of Laminar vs Turbulent Flow in a Straight Pipe

DOI:

https://doi.org/10.37934/sjotfe.7.1.2537aKeywords:

Laminar flow, turbulence flow, pressure dropAbstract

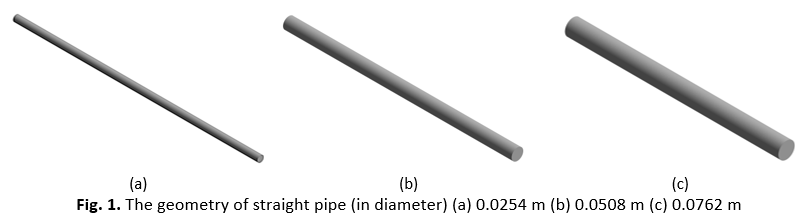

Pipelines are commonly used in industrial systems to transport fluids, and their performance is strongly affected by pressure losses that occur along the pipe. These losses depend greatly on the flow regime and the pipe diameter, especially when comparing laminar and turbulent conditions. Although many studies have investigated pipe-flow behaviour, limited attention has been given to how diameter changes influence pressure drop when both laminar and turbulent flows are analysed under the same conditions. In this study, this gap was addressed by examining how three pipe diameters (0.0254 m, 0.0508 m, and 0.0762 m) behave under two different flow regimes using Computational Fluid Dynamics (CFD). Simulations were performed in ANSYS Fluent, where laminar flow was modelled at 0.02 m/s and turbulent flow at 0.3 m/s using the realizable k–ε turbulence model. From the results, it was observed that the smallest pipe experienced the steepest pressure drop in both regimes, with turbulent pressure losses more than four times higher than in laminar flow due to stronger wall shear and intense momentum mixing. In contrast, the larger pipes showed slower pressure decay, smoother flow patterns, and only minor differences between laminar and turbulent conditions. Through this analysis, useful insights were provided for improving the design of straight-pipe systems, where selecting an appropriate diameter can reduce energy losses, improve flow efficiency, and enhance the overall performance of fluid transport operations.