Simulation of Turbulent Flow in Helical Coil Pipe

DOI:

https://doi.org/10.37934/sjotfe.6.1.1527aKeywords:

CFD simulation, helical coil pipe, turbulent kinetic energy, pressure drop, velocity profile, turbulence intensity, flow behavior, centrifugal effects, dean vortices, curved pipe flowAbstract

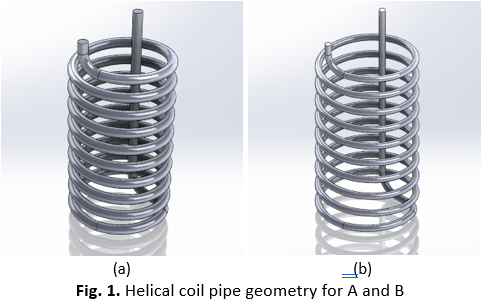

Many systems involving heat or mass transfer use helical coil pipes due to their small size and strong transfer properties. Because their shape is curved, the flow inside the pipe changes, so analysing accurately is crucial for achieving good performance. However, it is still difficult to understand how turbulent flow relates to the diameter of the pipes under different conditions. The goal of this study is to investigate the relationship between the diameter of a coiled pipe and how turbulent flow develops in terms of pressure, how velocity changes and how turbulent conditions occur. In SolidWorks, 2 helical coils were created to have the same coil pitch and number of revolutions (15 mm and 10 mm). Standard k–ε turbulence model in steady-state, incompressible flow was used in ANSYS Fluent to conduct CFD simulations. A grid independence analysis was conducted to check if the mesh was stable. The process was modelled using input speeds of 0.297 m/s, 0.397 m/s and 0.497 m/s for the inlet. It was found that the pipe with a smaller diameter led to an increase in pressure drops due to the added forces from both the walls and the centrifugal force. Tests showed that the flow’s velocity is high in the middle and less in the wall regions. Turbulence increased in areas where the flow was close to bends, though Dean vortices did not develop at the specified conditions. Ultimately, the investigation revealed that the size of the pipes has a big impact on the turbulence found inside the coils. Thanks to these findings, fluid system engineers have better control over their coils in terms of pressure and equal flow distribution.