Simulation of Turbulent Flow in a Pipe with Multiple Internal Obstacles

DOI:

https://doi.org/10.37934/sjotfe.6.1.2841aKeywords:

Turbulent flow, internal obstacles, pipe flow simulation, k–ω SST model, computational fluid dynamicsAbstract

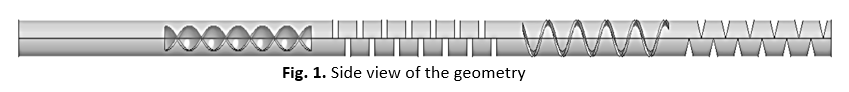

Turbulence in pipes and tubes is commonly observed in industrial systems, especially when internal obstructions cause flow disturbances. Understanding such flow behaviour is essential for enhancing system efficiency and reducing energy losses. This study aims to investigate turbulent fluid flow within different sections of a mechanical system using Computational Fluid Dynamics (CFD) simulations. The primary objective is to analyse how the fluid behaves under various configurations and to compare results across different scenarios to gain deeper insights into turbulent internal flow. In this simulation, the influence of internal obstacles on velocity and pressure distribution is explored. Two types of pipe geometries are considered, both containing square obstacles; however, their diameters differ to 1.5 cm and 3.0 cm respectively. Additionally, the obstacle sizes are proportionally scaled to match each pipe diameter. Three inlet velocities are used: 0.297 m/s, 0.397 m/s, and 0.497 m/s. These variations allow for the examination of how increasing flow intensity affects fluid characteristics and energy losses. The simulations are carried out using the k-ω turbulence model, which is appropriate for modelling incompressible turbulent flows. Meshes are generated with appropriate resolution and boundary conditions to ensure simulation accuracy. The results indicate that both the obstacle size and pipe diameter significantly influence the turbulence. Larger obstacles tend to increase turbulence intensity, while wider pipes facilitate smoother flow by reducing velocity gradients. Higher inlet velocities induce greater turbulence, emphasizing the role of internal geometry in shaping flow patterns. Velocity and pressure profiles are analysed and compared numerically across all cases. These findings suggest that optimizing obstacle shape and size, relative to pipe diameter and inlet velocity, can effectively control pressure drops and achieve desired flow characteristics.