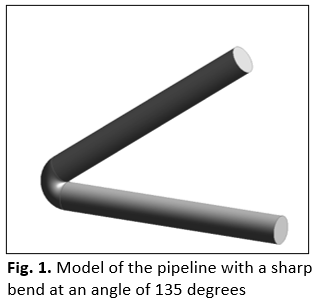

Simulation of Turbulent Flow in Various Internal Flow Geometries of Flow in a Pipe with a Sudden Turn (Sharp 135-Degree Bend)

DOI:

https://doi.org/10.37934/sjotfe.6.1.114aKeywords:

Turbulent flow, pipe bend, computational fluid dynamics, flow separation, pressure distribution, secondary flow structures, velocity profile, sudden turn, internal flow analysisAbstract

Designers of efficient fluid systems must understand turbulent flow in different, complex pipe shapes. Such flow dynamics are best altered by abrupt changes in diameter such as when a pipe bends out of shape. This work concentrates on the difficulties of studying water flow through a pipe that has a sharp bend of 135 degrees. These small-scale changes in geometry are responsible for creating flow separation, building secondary flows and increasing the pressure losses, damaging the performance of the system. Careful prediction of these phenomena is required for engineering uses in both HVAC and process industries. This research mainly aims to understand how abrupt directional changes impact the separation of flow, the pressure lost and the growth of secondary vortices within the pipe. The intention is to observe how turbulence within boundaries changes and to apply those findings to the development of energy-efficient designs. Improvements in aerodynamics were evaluated with CFD simulations in ANSYS Fluent using the standard k-ε model for steady situations. Room temperature water was used for this experiment. With inlet velocities of 0.297 m/s, 0.397 m/s and 0.497 m/s and corresponding Reynolds numbers at 4,338 around each, we confirmed the presence of turbulent flow. Because the diameter of the pipe needed to be comparable, it was always set at 1.50 cm. A grid independence study revealed that the flow results in the bend area were unaffected by changes in mesh. The motion in the model shows definite regions for the breakup of flow at the inner bend and highlighted secondary flow zones caused by strong recirculation. Extra secondary vortices were seen forming beside the inner bend wall, making it clear that the flaws of straight-pipe assumptions are now visible. As a result, this bend disrupts the smooth flow and forms difficult patterns of turbulence. This work points to the importance of using advanced simulations to predict and handle these impacts in fluid systems.