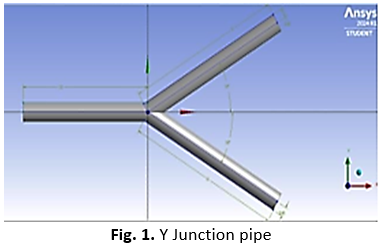

Integrating CFD Tools for the Simulation and Analysis of Turbulent Flow Dynamics in a Y-Junction Pipe

DOI:

https://doi.org/10.37934/sjotfe.5.1.4654aKeywords:

Y-junction pipe, energy loss reduction, velocity profiles, pressure distribution, flow separationAbstract

The study uses computational fluid dynamics (CFD) to examine turbulent flow behavior in a Y-junction pipe. Y-junctions are frequently used in fluid distribution engineering systems, where performance optimization and energy loss reduction depend on an understanding of flow dynamics. To provide accurate turbulence modelling, the simulation is run in ANSYS Fluent under turbulent circumstances using water as the working fluid and a Reynolds number of 3840. Important elements are examined, including velocity profiles, pressure distribution, flow separation, secondary flow structures, and turbulence intensity. To verify the precision and dependability of the simulation findings, a grid independence test is conducted. The study emphasizes how the shape of the Y-junction affects fluid behavior, including pressure decreases and vortex generation. With possible uses in industrial pipes, HVAC systems, and chemical process equipment, the results offer insights into enhancing Y-junction designs by reducing turbulence and maximizing flow uniformity.