Comparative Study of Internal Flow Dynamics Using CFD: Flow in a Curved Elbow with Variable Radius

DOI:

https://doi.org/10.37934/sjotfe.6.1.5769aKeywords:

Computational fluid dynamics (CFD), velocity profile, pressure distribution, turbulence intensityAbstract

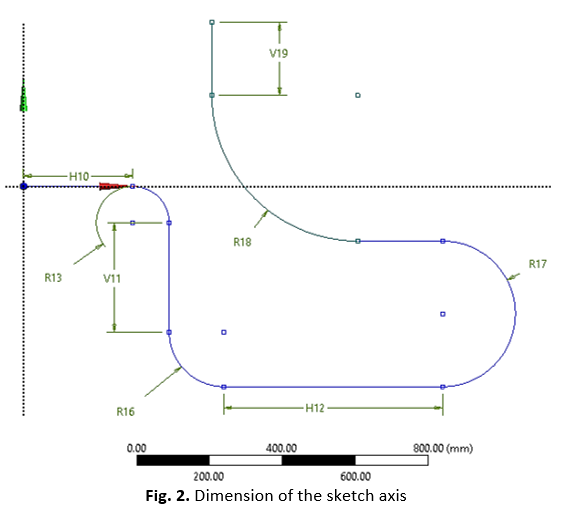

The efficiency and quality of many industrial processes depend on the design and handling of piping systems, as changes in pipe diameter and speed of flow can greatly affect fluid movement. Since these factors impact the way flow operates, they are important to understand to ensure the system runs well, wastes less energy and stays reliable. However, properly predicting pressure, velocity and turbulence levels in pipelines with turns or irregular shapes is challenging because of how fluid dynamics and the pipe’s structure interact. Frequently, approaches used before finding it difficult to handle the complexities; therefore, improvements in numerical techniques are required. We will investigate how reducing pipe diameter and increasing inlet velocity changes the flow characteristics in two independent tubes of 150 mm and 200 mm. Using Fluent software from the ANSYS platform, simulations were done at inlet velocities of 0.247 m/s, 0.397 m/s and 0.497 m/s. The analysis examined important characteristics of flow, including the pressure distribution, the velocity profile and the strength of turbulence, mostly in the regions just after pipe bends. According to simulation results, higher inlet velocity results in more pressure drops, sharper velocity gradients and larger turbulence levels in both pipe shapes. Higher levels of pressure and velocity changes, together with increased turbulence, were seen in the 150 mm diameter pipe at higher velocities. When we used the bigger size pipe (200 mm), the results indicated less pressure decrease and less change in the flow, showing the value of greater pipe size in saving energy and keeping the flow consistent. Overall, this research points out that pipe diameter and flow velocity play a major role in how well piping systems perform. The study results give helpful guidance for developing and improving stable and reliable piping systems in factories and plants.