Numerical Analysis of Mixing Tank with Top Entry and Side Entry Agitator Using Computational Fluid Dynamics

DOI:

https://doi.org/10.37934/sijfam.6.1.113Keywords:

Fuel mixing process, storage tank, agitator, CFDAbstract

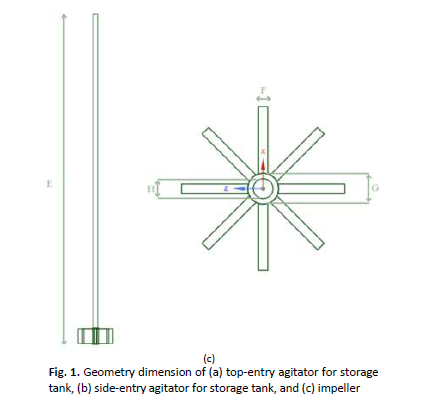

The procedure of mixing fuel in storage tanks is critical for ensuring fuel homogeneity and quality prior to distribution. The use of agitators as stirring devices in storage tanks helps to reduce stratification and accelerate mixing. This study used Computational Fluid Dynamics (CFD) with ANSYS 2024R2 using the k-epsilon realizable model approach to evaluate the effectiveness of agitators at 300 and 600 rpm in optimizing the fuel mixing process for heavy naphtha and paraffin into a homogeneous product for public vehicles. Simulations were run to determine the impact of rotational speed, impeller type, and agitator position on flow distribution and mixing times. The results showed that the side entry agitator had a higher torque than the top entry agitator, reaching 3,663 Nm at 300 rpm and 14,997 Nm at 600 rpm, compared to 3,266 Nm and 13,416 Nm for the top entry agitator. Consequently, the power required for side entry agitators was 115.054 kW (300 rpm) and 942.261 kW (600 rpm), while top entry agitators required 102.585 kW (300 rpm) and 842.927 kW (600 rpm). Pressure distribution was highest in the side entry agitator at 600 rpm, leading to a stronger wall shear distribution and faster mixing. Mixing time was significantly reduced with side entry 600 rpm, achieving 75 seconds, compared to 400 seconds for top entry 600 rpm. Additionally, placing the agitator in the vertical center position produced a more equal flow pattern, accelerated homogeneity, and prevented fuel-phase separation. Once the mixing process was complete, the final fuel density was recorded at 722.1 kg/m3. These findings have significant implications for creating more reliable and energy-efficient blending systems in the energy industry.