Lightweight Plastic-Cellular Concrete Block (LPCCB) for Construction Applications over Peat Ground

Keywords:

Lightweight fill block, plastic, cellular concrete, rubber-sand mixture, foam agentAbstract

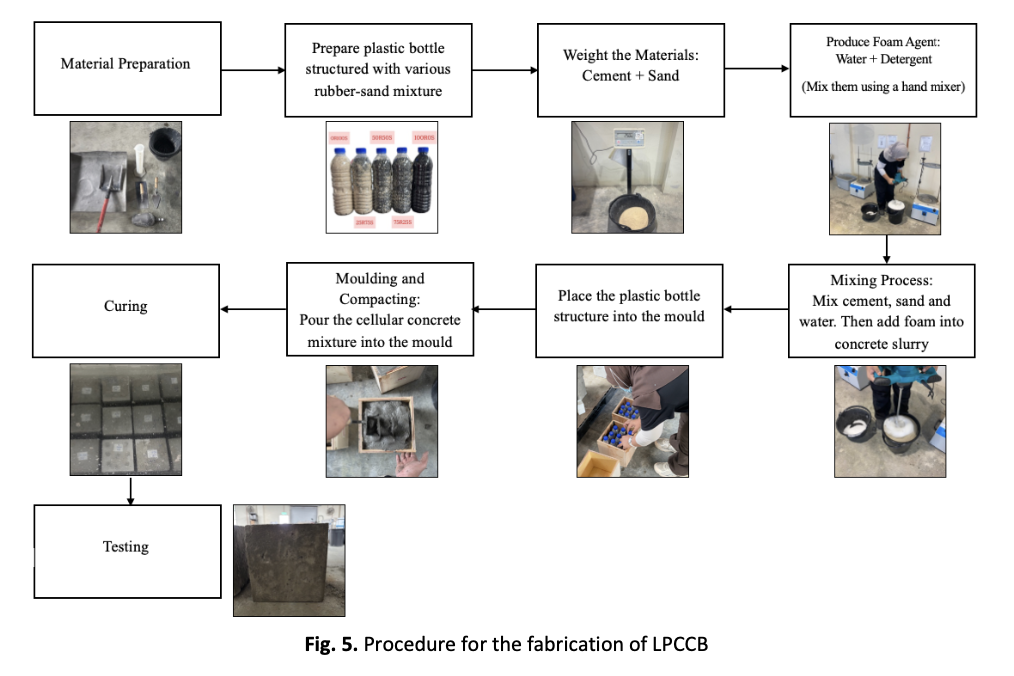

The rapid infrastructure development has forced construction over peat ground, causing a rising need for innovative construction solutions without replacing the existing soil. This paper aims to investigate an alternative lightweight fill material derived from by-products as a substitute for the unsustainable and expensive soil replacement method. This study incorporates recycled plastic bottles filled with rubber-sand mixtures as the primary structural component within a cellular concrete matrix, referred to as Lightweight Plastic-Cellular Concrete Block (LPCCB). The study was divided into three experimental phases to assess the mechanical and physical performance of the proposed lightweight fill block: (1) bottle structure containing various rubber-sand mixtures, (2) cellular concrete mix design, and (3) LPCCB developed based on findings from Phases 1 and 2. The results demonstrate that the densities of filled plastic bottle structures increased in a linear trend with the increase in sand content in the bottle structures. The study found that the 75R25S rubber-sand mixture exhibited the greatest compressive strength (6.40 MPa), with a density less than 1000 kg/m3. The cellular concrete properties showed that the compressive strength continued to decrease with the increase in foam content, consistently demonstrating a decrease in both density and compressive strength, while also increasing porosity and water absorption. In the final phase, the fabrication of LPCCB has used foam agents of 0.5, 1.0, and 3%. The findings showed that utilising foam more than 1% led to structural failure. Overall, it can be concluded that the rubber-sand mixture plays an important role in terms of density and strength, and that the 0.5% foam agent creates a solid and sturdy grasp of the plastic bottle. This research adds to more sustainable construction designs and applications, combining both recycled plastic and rubber waste to make it a structural material with a lightweight approach, with no negative impact on the environment in soft soil conditions, including peatlands.