Quality Improvement of SKT Cigarette Products (A Case Study)

DOI:

https://doi.org/10.37934/spaset.2.1.114Keywords:

quality control, DMAIC, SKT cigarettesAbstract

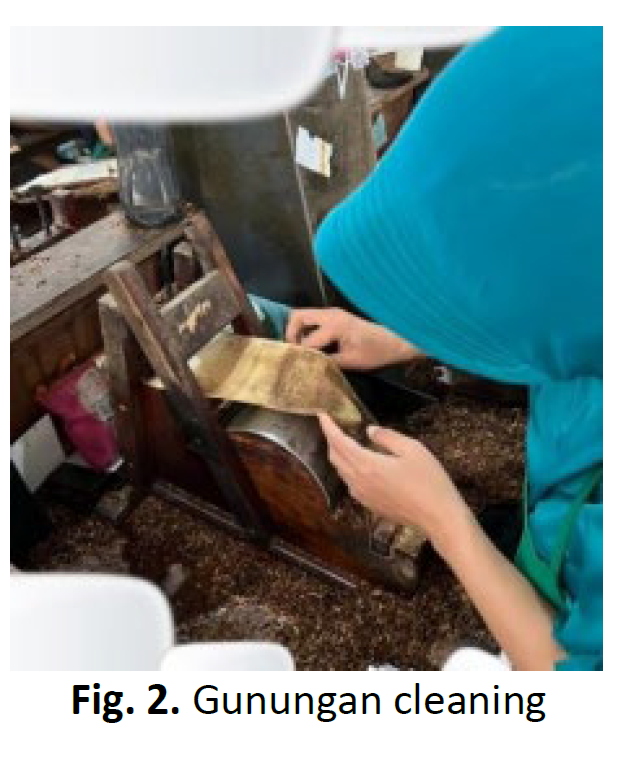

Product quality is a feature that can fulfil the desires and needs of consumers so that consumers can feel happy and satisfied with the product. One of the products currently often used is cigarettes. Cigarettes are processed tobacco from the Nicotiana tabacum, Nicotiana rustica, and nicotine plants. The cigarette tobacco will be dried first and then put onto cigarette paper. There are two types of cigarettes: SKM (machine-made kretek cigarettes) and SKT (hand-rolled kretek cigarettes). SKT requires high creativity, so the quality control process must be considered. PT X is one of the cigarette factories domiciled in Malang City, and the percentage of defective SKT cigarettes at PT X is high (11,72%), exceeding the target. The expected target percentage of SKT cigarette defects is less than 10%. The stages and tools used to solve this problem are DMAIC, Pareto Diagrams, and 5 Why's Analysis. Based on the Pareto diagram, five primary defects must be corrected immediately: loose cigarettes, lack of glue, sangan defect, not symmetrical embroidered paper, and not precision diameters. The root causes of each type of smoking defect can be analysed using the 5 Why's Analysis tools and proven by data. The improvement implementation was carried out by changing work methods, work tools, and workers' bad habits. The implementation results showed that the target percentage of defects in SKT cigarettes decreased to 9.47%. PT X applies SOP, checklists for improvement plans, and defect data recap to maintain their performance.