Numerical Analysis of Heat Transfer and Temperature Distribution in Molten Sodium Casting using ANSYS Fluent

Keywords:

Ansys Fluent, casting, temperature, molten sodiumAbstract

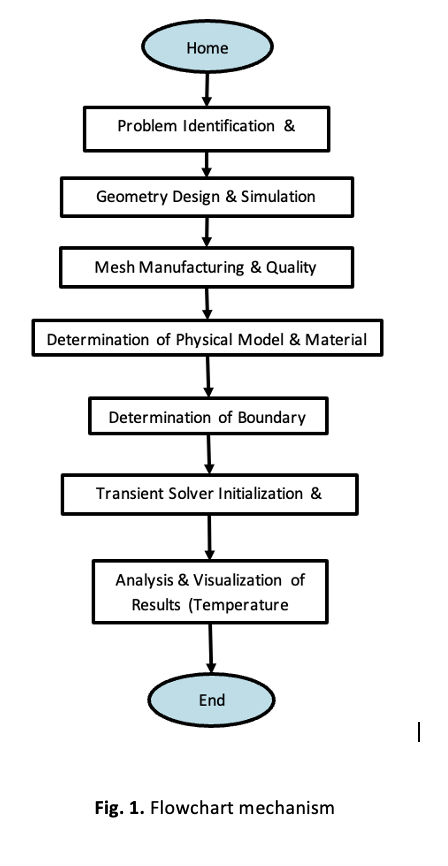

This study numerically investigates the heat transfer and temperature distribution of molten sodium during the casting process using Computational Fluid Dynamics (CFD). Unlike previous studies that focused on conventional metals such as aluminum and steel, this research addresses the limited understanding of high-conductivity fluids like molten sodium in complex mold geometries. A three-dimensional simulation of a T-junction mold reveals that heat transfer is initially dominated by convection and later by conduction as the system approaches equilibrium. Temperature uniformity is achieved after approximately 150 seconds, with a maximum temperature difference below 20 K, indicating high thermal stability. Comparison with aluminum-based studies (Yuwen et al.,) validates the numerical model and confirms molten sodium’s superior heat transfer capability. The findings highlight molten sodium’s potential as an efficient and stable heat transfer medium and underscore the importance of mold geometry and thermal control in achieving high thermal efficiency in casting systems.