Optimizing Heating-Cooling Performance by Retrofitting Cooling Element in Continuous Stirred Tank Pre-Treatment Bioreactor Design

DOI:

https://doi.org/10.37934/sijmpe.3.1.3240Keywords:

Continuous stirred tank reactor, heating cooling element, CFD analysisAbstract

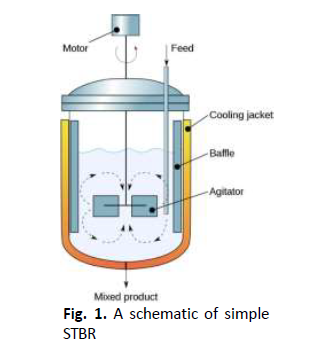

The physical processes inside stirred tank bioreactor (STBR), including mixing, reaction kinetics, and heat transfer is commonly studied in bioprocess design. STBRs have better heat transfer properties than batch reactors, which means that heat can be more easily and efficiently removed from the reaction mixture. These criteria help to prevent overheating and improve reaction efficiency. The current issue of longer heating and cooling time in pre-treatment STBR during pyrolysis of biomass products has led to this research by adding the cooling element inside the stirred tank. CFD analysis results for heating duration of the proposed retrofit design and comparison of cooling analysis between CFD simulation and site test data are to be presented and discussed in these studies. The result shows that the reactor can be retrofitted with additional internal coil with new temperature control unit (heating & cooling) to achieve heating duration by reducing time within 1 hour.