Determination of Control Valve Maintenance Interval using RCM Method at Pertamina Refinery Unit V Balikpapan

DOI:

https://doi.org/10.37934/sijmpe.2.1.110aKeywords:

Control valve, maintenance interval, reliability centered maintenance, FMEA, mean time to failure, mean time to repairAbstract

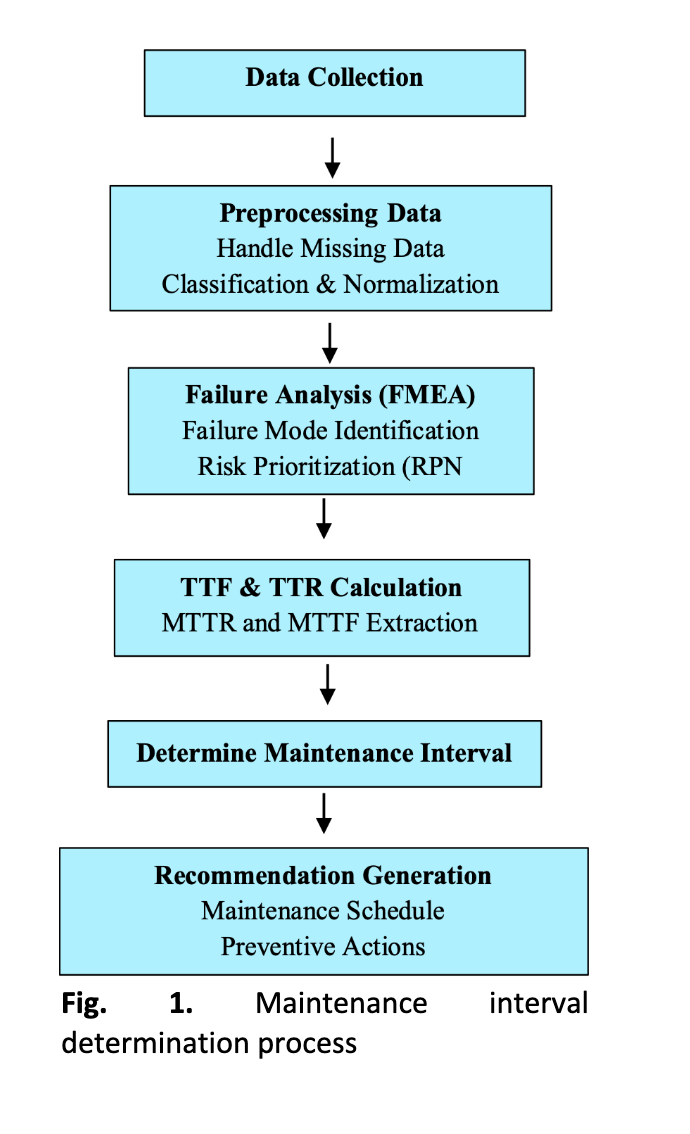

The Pertamina Oil Refinery Unit V in Balikpapan is a crucial infrastructure in Indonesia’s oil and gas industry. One of the critical components in this refinery is the control valve, specifically the control valve with tag number 02-LCV-084, which has experienced frequent malfunctions. This study aims to determine the optimal maintenance intervals for the control valve using the Reliability Centered Maintenance (RCM) methodology. The research involves analyzing two years of failure data and applying techniques such as Failure Mode and Effect Analysis (FMEA), Time to Failure (TTF), and Time to Repair (TTR) calculations. The results indicate that the seat ring requires maintenance every 757 hours (32 days), the plug every 874 hours (37 days), and the stem every 1694 hours (70 days). These maintenance intervals provide important insights for improving the operational efficiency of the refinery’s equipment by preventing unscheduled downtime and reducing repair costs. The implementation of RCM in determining maintenance intervals can enhance the reliability and longevity of critical equipment in industrial environments.