Hazard Identification and Failure Analysis in Grinding Process

DOI:

https://doi.org/10.37934/sijmpe.1.1.110aKeywords:

Selected:Grinding process, hazard identification, failure analysis, simulationAbstract

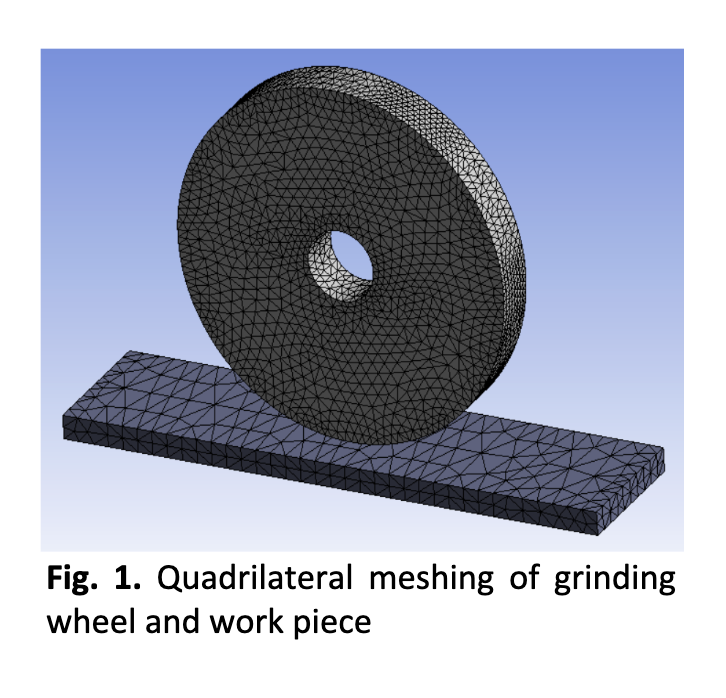

The grinding process is a material removal technique to shape and refine various materials. By using an abrasive wheel, flat or cylindrical surfaces can be shaped and often used as a finishing process in product making. However, the process has the potential to cause serious harm if handled inappropriately specifically with regards to the rotating abrasive wheel. This work aims to identify and analyse the root causes leading to grinding process failures. It involves a review of relevant literature on accidents and potential hazards. Next, the information was clustered by using an affinity diagram and the category with the highest frequency was selected which is ergonomics. After that, hazard identification and risk assessment were conducted on the ergonomics category to identify the activity with the highest risk. Strengths, weaknesses, opportunities and threats or SWOT analysis was utilized to select the most significant activity to be simulated. The design was created by using SpaceClaim software and the simulation was analysed by using ANSYS software. Through the simulation, it was found that at normal grinding force of 1800 N, the deformation is 0.0045 mm and the equivalent (von Mises) stress is 26.3160 MPa. The findings help to promote a safe working condition and the appropriate use of grinding equipment especially when there is contact with rotating parts.