Bimetallic Supported on Bivalve Calcium Catalyst for Catalytic Transfer Hydrogenation of Pyrolysis Tire Oil: Effect of Composition

DOI:

https://doi.org/10.37934/sijcpe.4.1.2232Keywords:

Tire pyrolysis oil, catalytic transfer hydrogenation, bimetallic catalyst, D- limonene, sulfur removalAbstract

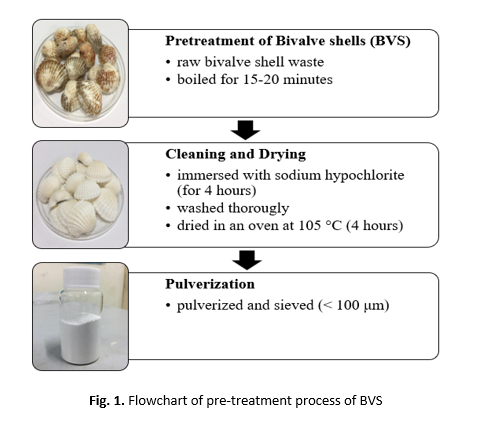

Scrap tire pyrolysis oil (TPO) is a promising source of valuable chemicals, notably terpenes for various industrial applications. However, its complex composition and high sulfur content necessitate effective upgrading methods. This study explores the catalytic transfer hydrogenation of TPO using bimetallic nickel-cerium (Ni-Ce) catalysts supported on bivalve shell waste (BVS), a sustainable and low-cost catalyst support. Catalysts were synthesized via a conventional wet impregnation and subsequently evaluated under identical catalytic transfer hydrogenation conditions at varied Ni-Ce ratios (1:5, 3:3, 5:1) to determine their influence on product distribution and sulphur removal efficiency. Among these tested formulations, the 3:3 Ni-Ce/BVS catalyst achieved superior performance, achieving the highest liquid yield, producing 25.67% D-limonene- a valuable terpene compound while simultaneously achieving complete removal of sulphur- containing compounds from the pyrolysis oil. Detailed catalyst characterization confirmed key structural and functional features responsible for enhanced performance. XRD patterns confirmed the formation and stabilization of well-defined crystalline nickel and cerium oxide phases within the catalyst structure with the calcination process notably enhancing the overall crystallinity and phase purity. Furthermore, FTIR analysis detected significant modifications in the surface functional groups of the catalysts, including shifts and intensity changes in characteristic peaks associated with hydroxyl, carbonate and metal-oxygen bonds. These modifications are indicative of successful metal incorporation and interactions with the BVS support which are essential in promoting effective hydrogen transfer and hydrocarbon conversion reactions. This work advances sustainable TPO upgrading techniques and underscores the potential of waste-derived materials for eco-friendly catalytic applications.