Optimization of 3D Printing Parameters for PLA Spur Gears using the Taguchi Method and Response Surface Methodology

DOI:

https://doi.org/10.37934/sijaset.6.1.116Keywords:

Dimensional accuracy, 3D printing parameters, Polylactic Acid (PLA), Taguchi Method, Response Surface Methodology (RSM)Abstract

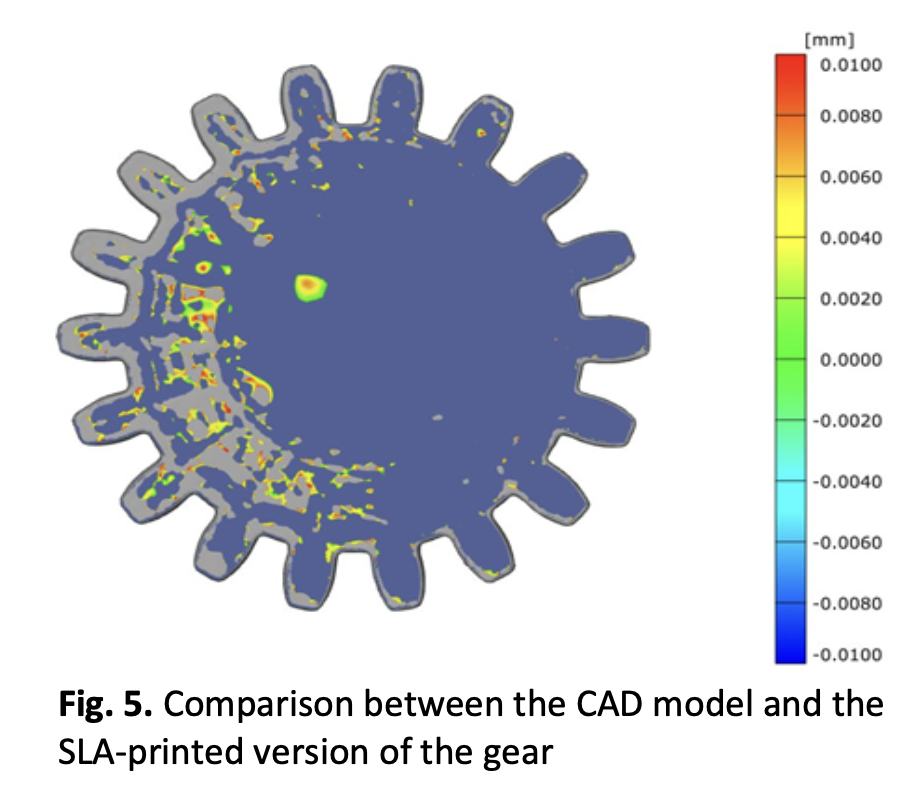

The dimensional accuracy of 3D-printed components is a significant challenge in precision engineering, particularly for functional parts such as spur gears. Variations in printing parameters often result in dimensional deviations, which can compromise the performance and reliability of the final product. This research investigates the influence of key 3D printing parameters—layer thickness, infill density, and printing speed—on the dimensional accuracy of polylactic acid (PLA) spur gears. The study employed the Taguchi Method, using an L9 orthogonal array, to identify critical factors and their interactions. At the same time, Response Surface Methodology (RSM) was utilized to develop a detailed response model for optimization. Findings revealed that printing speed significantly impacted dimensional accuracy, layer thickness, and infill density. By optimizing these parameters, substantial improvements in dimensional precision were achieved, reducing deviations and enhancing overall quality. The optimized settings demonstrate the potential for refining 3D printing processes to produce precise and reliable components. This study underscores the importance of statistical approaches in additive manufacturing and offers valuable insights for industries seeking to produce high-quality functional parts.