Investigation of the Flow Inside Coal Pulveriser with Varying the Vane Angle

DOI:

https://doi.org/10.37934/sej.8.1.3750bKeywords:

Coal pulveriser, vane angle, computational fluid dynamic (CFD), discrete phase model (DPM)Abstract

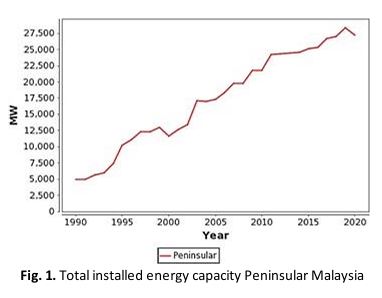

Coal and natural gas are used to generate almost 93% of electricity in Peninsular Malaysia. While the use of coal in the energy industry increases, the impact of coal burning on the environment should be emphasized. Incomplete combustion in boilers frequently results in a substantial amount of unburned carbon in the ash and pollutant emissions. A key factor in resolving this issue is to improve classification quality by achieving a higher particle separation quality in which at least 70% of the coal particles leaving the classifier are smaller than 75μm. The effect of the flow inside the coal pulveriser with varying vane angles (45° and 60°) on classification in coal-fired power plants was investigated using three-dimensional (3-D) computational fluid dynamics modelling. The realisable k-ε turbulence model (RKE) with a detailed 3-D coal pulveriser geometry was used to solve the flow inside the coal mill, while the discrete phase model was used to solve the coal particle flow. The coal mill with a vane angle of 60° resulted in better escaped particles with 69.35% of the coal particles with 50-micron size escaped and 59.68% of coal particles with 75-micron size escaped from the outlet. The flow pattern inside the coal mill for the 60° vane angle model is also fine which is swirling from the bottom of the tank.