The Effects Strength & Density of Autoclaved Aerated Concrete Containing Recycled Rubber (AAC-RR) on Insulation Application

DOI:

https://doi.org/10.37934/sej.8.1.112bKeywords:

Recycled rubber, autoclaved aerated concrete (AAC), strength, densityAbstract

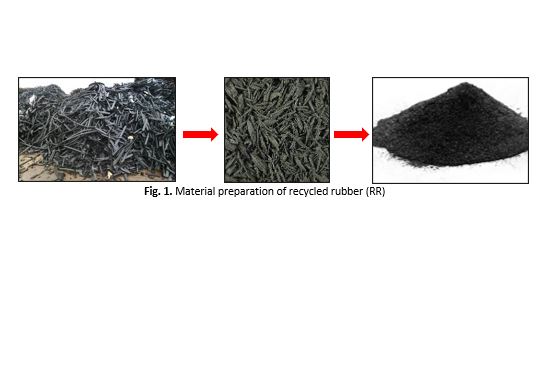

This research presents the properties of Autoclaved Aerated Concrete (AAC) based Recycled Rubber (AAC-RR) is used as a partial replacement for sand in lightweight panels. Adding recycled rubber helps decrease environmental waste, improve sustainability, and enhance the material's strength, modulus young, modulus rupture and density, potentially reducing production expenses. The AAC-RR were made by substituting sand with recycled rubber at varying levels of 0%, 5%, 10%, 15%, 20%, and 25%, utilizing typical components such as cement, sand, water, and 1% aluminum paste. The findings from the experiment show that the AAC-RW of 10% recycled rubber offers the optimal combination of strength and sustainability, with a dry compressive strength of 1.960 MPa, a density of 0.867 g/cm³, and a Young's modulus of 0.680 GPa in line with the desired density of 750 kg/m³. The 10% AAC-RW provides potential to be applied into insulation panel due to its low weight characteristics. It is revealed that AAC-RR from recycled rubber materials help in improve both performance and environmental benefits.