A Case Study on the Use of a Powered Exoskeleton for Oil Palm Harvesting

DOI:

https://doi.org/10.37934/scbtrj.5.1.110Keywords:

Exoskeleton, muscle activity, oil palm, harvesting, performance, productivityAbstract

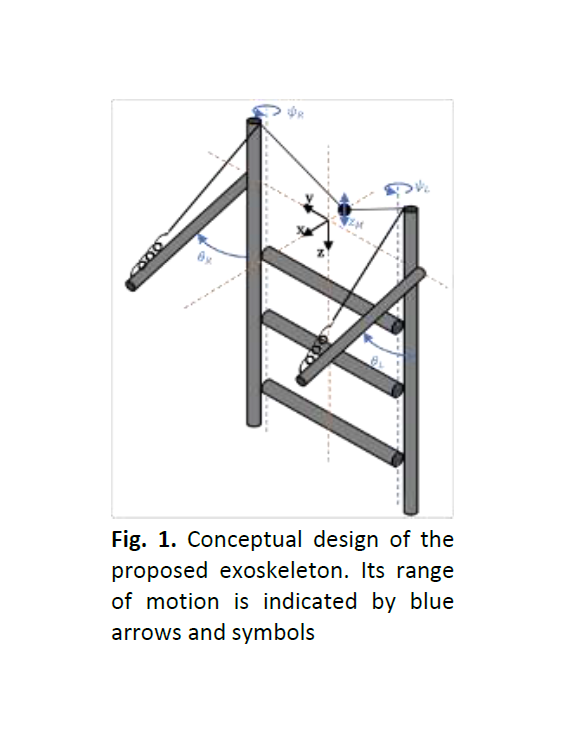

A worker's performance is affected by his physical fitness, environmental conditions, interaction with work tools and work postures. It is also recognized that fatigue can be indicated by physiological signals, such as muscle activity and heart rate. When harvesting oil palm trees, a worker needs to execute his tasks in challenging environmental conditions and poor ergonomic working condition, such as handling a long harvesting tool and performing repetitive motions for an extended duration. This study investigated the immediate effect of a prototype exoskeleton on harvesting workers, which aim to assist workers in handling the harvesting tool. The changes in selected upper limb muscle activities when performing the targeted tasks while using and not using the exoskeleton prototype was observed. Results indicated the activity of all observed muscles reduced when harvesting while wearing the exoskeleton. The average RMS improvement when using the exoskeleton for harvesting motion in all four muscles is approximately 22%.A full-scale field trial is necessary to evaluate the effects of the proposed solution toward workers’ and harvesting productivity.